All You Need To Know About ESD Bench Mats

If your employees often handle electrical items susceptible to static electricity harm, your company should most likely use Electro-Static Discharge (ESD) matting. ESD matting is easily neglected since it is an important yet essential aspect of your working environment. That is why we have created this helpful guide about ESD bench mats.

Fundamentals of ESD matting

The most important thing to understand about ESD matting is that it protects equipment from static electricity discharges. ESD bench mats are typically used on workstations where charges might accumulate. ESD matting typically consists of a static dissipative top layer and a conductive bottom layer. An ESD mat provides a straightforward path to the ground for static electricity.

Static discharges can damage electronic equipment if an ESD mat does not protect it. Some electrical components can be damaged by as low as 5v static discharge. ESD mats, when used in conjunction with additional measures such as anti-static tools, clothes, footwear, flooring, packaging, and grounding straps, safeguard your products and processes against hidden harm caused by static discharges.

Where do you usually put ESD matting?

It's also worth noting that ESD mats can help in locations where static electricity occasionally occurs. Electronic gadgets, for example, that have been packaged up in protective wrapping may still need to be housed in warehouses and storage spaces. ESD matting is frequently used on storage shelves to offer an extra layer of static protection from stacking.

ESD mat varieties

We couldn't title this piece "all you need to know about ESD matting" unless we discussed the vast varieties of ESD mats available.

Bench covers

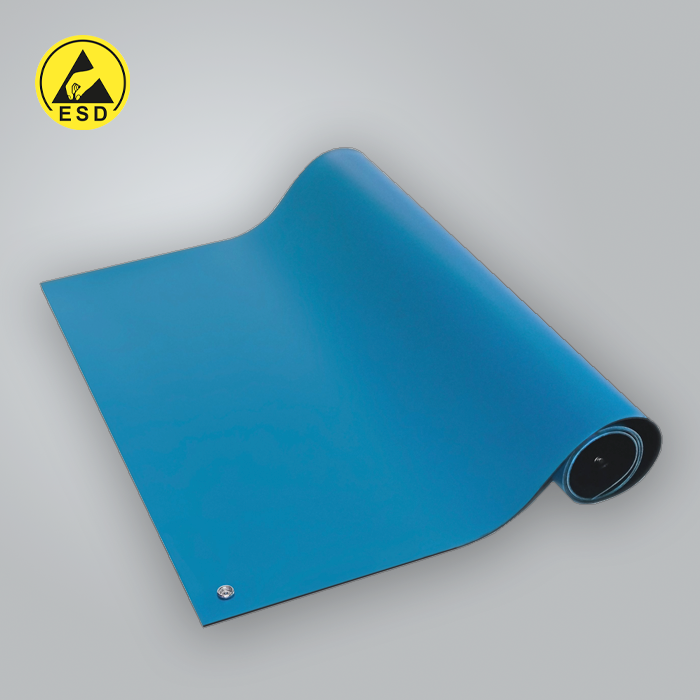

ESD mats for work surfaces are often thinner than floor mats. They are often available in either smooth or faintly embossed covers, with the latter reducing glare and assisting employees with complex electrical assembly chores. With this in mind, bench mats are typically brightly colored to assist workers in finding tiny components on their surface, and they are intended to be used in conjunction with other ESD controls such as wrist straps and grounding points.

Mats for the floor

ESD floor mats are intended to be part of a larger ESD protection strategy that includes products such as ESD boots. Because they must withstand more significant wear and tear, underfoot ESD mats are often bigger and thicker than bench mats. They have deeper embossing or grooves to prevent employees from sliding. Furthermore, many are cushioned to make standing on them for hours more pleasant. They're usually black to hide dirt and scuffs from employees' shoes, but this might make it harder to spot components if they fall from the worktop into the floor.

Grounding wrist strap and ESD mat

ESD matting compositions are classified into four categories. Each provides varying degrees of static resistance and is often utilized for different purposes. One of the fundamentals of ESD matting is that it is measured in three ways:

The primary measurement and the one we'll concentrate on are in the examples following. The resistance provided between the most heavily utilized region of the ESD mat and the electrical ground is measured by RTG.

Ending Up!

Hope, you are well versed with the ESD mats in detail. If you are looking to buy the esd mats, then Grove Sales Limited is your place to visit. They are amongst the top ESD mats providers around the globe. Refer to their website for more details!

Comments

Post a Comment